4 MODELS, ONE PROMISE:

Performance, you can count on.

If you’re looking for a machine which is robust, ready for the anything and easy to operate, you’re right on target with the Altendorf WA 8. Whether you’re squaring panels or cutting complex angles and mitres, the Altendorf WA 8 is the right companion for you. Manufactured to Altendorf’s rigorous technological standards, the WA 8 entices with its solid build quality and ergonomic flexibility. As soon as you have one, you’ll wonder how you ever managed without one. That’s what happens when you decide to invest in the high quality only the world market leader can provide.

WA 8 NT

A modern classic: The Altendorf WA 8 NT with manual rise/fall adjustment of the main saw blade.

Providing accurate, clean cuts and easy to operate, the Altendorf WA 8 NT is the ideal machine for cutting panels to precise dimensions. The control panel is simple to use and both the rip fence and the crosscut fence are easy to set up.

The Altendorf WA 8 is not available in all markets.

The standard equipment of the machine may vary from country to country.

Manual rise/fall adjustment.

Manual rise/fall adjustment of the main saw blade, non-tilting saw unit

Sliding table.

The Altendorf sliding table is renowned for its smooth and exact running. This is hallmark of an Altendorf, and it all comes down to design: the table runs on large dumb bell rollers sandwiched between hard chromed guide bars, guaranteeing absolute precision. The system’s large rollers ensure smooth action, meaning the table takes less effort to move and glides as securely as if it were on rails. This quality running will endure decades of heavy load bearing in the constant presence of dust and chips, and it needs virtually no maintenance. Each time the table moves, the brush fitted to the upper part automatically cleans the round guide bars. The system operates without any lubrication. The table’s hollow multi-chamber aluminium extrusion guarantees optimal torsion resistance and rigidity. The principle of the sliding table. Wilhelm Altendorf discovered that the only way to achieve an absolutely straight edge, which in turn is required as a reference edge for precise rip and crosscutting, was to guide a static work piece through the rotating saw blade by holding it firmly on a moving support. To begin with, Wilhelm Altendorf used a wooden push slide system to guide the workpiece. In the 1930s, Altendorf developed the double roller carriage. Since the development of the aluminium sliding table in the 1950s we know of no better system than the double roller carriage in terms of smooth running, precision, torsion-resistance and low maintenance. Over 130 000 users worldwide agree with us.

Rip fence.

The rip fence is smooth and precise to adjust. The hard chromeplated round bar ensures the fence moves smoothly. If you need to divide large panels, you can swing the rip fence away under the level of the machine table.

Crosscut fence.

The robustly mounted crosscut fence enables precise cutting of 90° angles. All settings are easy to read off the slanted scales. The flip stops are robust, free of play and are easy to slide individually along the full crosscutting range.

Motor rating.

Motor rating 5.5 kW (7.5 HP), with three speeds 3/4/5 000 rpm, manually adjusted

Cutting height.

Cutting height max. 82 mm

Machine frame control panel.

The controls mounted on the panel on the machine frame are clearly identified and easy to operate. The rise and fall of the main blade is via handwheel.

Extraction hood.

The riving knife mounted protection and extraction hood allows a maximum saw blade diameter of 315 mm with a maximum cutting height of 82 mm.

Machine frame.

The WA 8 has a torsion-resistant machine frame built in the same way as the machine frames for the F 45 series. The frame design ensures very smooth running and stability. The machine frame is fully enclosed.

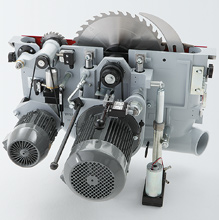

Saw unit.

The Altendorf saw unit is the engineering heart of all our saws. It is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly: this is because it is electronically balanced as a fully assembled unit, and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

Scoring unit with motorised adjustment.

The scorer prevents chipping out on the underside of laminated panels. The rise and fall is motorised, the lateral adjustment manual. When the scoring blade is switched on, the scorer moves to the height stored. When either the main or scoring blade is switched off, the scorer moves back under the table. The scorer has an independent 0.75 kW (1 HP) motor and turns at 8 200 rpm.

RAPIDO.

The RAPIDO scoring system makes it easier and quicker to adjust the cutting width to match that of the main blade. How quick? About three minutes, max! Compared to working with shims, where you have to take the blade off the machine to alter its width, the RAPIDO saves at least ten minutes, as the blade stays on the machine during adjustment. Adjustment is continuous so the RAPIDO can be fine-tuned to match any main blade.

Adjustment range: 2.8 – 3.8 mm.

Rip fence with fine adjustment.

Manual fine adjustment enables the rip fence to be adjusted precisely. The fence can be set with pinpoint precision by means of the adjusting screw.

DIGIT X.

A digital cutting width display for the rip fence with manual fine adjustment. This electronic measuring system guarantees rapid, precise adjustment of the rip fence. DIGIT X also offers repeat accuracy: the fence can be moved and then returned to exactly where it was previously. The system is immune to both wear and dust. Dimensions are corrected automatically when the fence is changed from the upright to the flat position.

Large extraction hood.

The large Altendorf extraction and safety hood system boasts a design which ensures optimised airflow. You can switch between narrow and wide hoods in seconds. The hood allows cutting heights of up to 125 mm (with or without scoring unit) and can be swung away fully to one side. This hood is available as an option for the WA 8 NT and WA 8 T.

DIGIT L.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings at the same time, and allows calibration of all stops in one operation.

DUPLEX.

The DUPLEX fence makes it possible to cut any angle between 0 and 90° very quickly and exactly. At 45°, the mitre can be cut on both sides of the workpiece without having to adjust the fence. The dimensions are set using a magnifying glass, measuring scale and length compensation scale. The fence can be positioned anywhere along the length of the sliding table.

One-sided mitre fence.

The one-sided mitre fence enables precise cutting of mitres. It is easy to set and can be positioned on the sliding table with the minimum of effort.

PALIN.

Long narrow workpieces can be cut parallel or into a conical shape with absolute accuracy using the PALIN fence. As the fence itself is flush with the sliding table in the vertical plane and the workpiece is laid sideways against the stop, there is no reduction in cutting length and workpieces of differing lengths can be cut without moving the fence up and down the sliding table. With the measuring system removed, the fence acts as an additional workpiece support. Also available in digital form as PALIN D.

STEG.

Enlarges support area (width: 400 mm) for wider workpieces. Makes it much easier to size large panels.

DUST EXTRACTION CONNECTION

| Top connection: | small extraction hood: Ø = 50 mm, large extraction hood: Ø = 80 mm |

| Bottom connection: | Ø = 120 mm |

| Pressure drop: | 1 500 Pa with a total connection diameter, Ø = 140 mm |

| Minimum air requirement: | Vmin = 1 150 m3/h at 20 m/sec. |

ELECTRICAL POWER REQUIREMENTS

| Motor (kW) | 5,5 |

| Voltage (V) | 380 – 420 |

| Frequency (Hz) | 50 |

| Current (A) without/with scorer | 11,5/13,5 |

| Fuses/circuit breakers (A) | 25 |

3) The cross section of the mains cable depends on the machine’s distance from the power source and must be determined by a qualified electrician (Power drop in the input cable ≤ 3 %). Please contact your Altendorf sales partner if your power supply does not match the requirements shown.

CUTTING WIDTHS

| Cutting widths (mm) | 1 000 | 1 300 |

SLIDING TABLE CUTTING LENGTH

| Maximum cutting lengths when using clamping shoe or crosscut fence | ||||

| Table length (mm) | 2 000 | 2 600 | 3 000 | 3 200 |

| Cutting length (mm) | 1 905 | 2 505 | 2 905 | 3 105 |

CUTTING HEIGHTS

| With or without scoring saw blade | |||||

| Saw blade diameter (mm) | 250 | 300 | 315 | 350 | 400 |

| Cutting heights, vertical (mm) | 0-50 | 0-75 | 0-82 | 0-100 | 0-125 |

| Cutting heights at 45° (mm) | 0-33 | 0-50 | 0-56 | 0-70 | 0-87 |

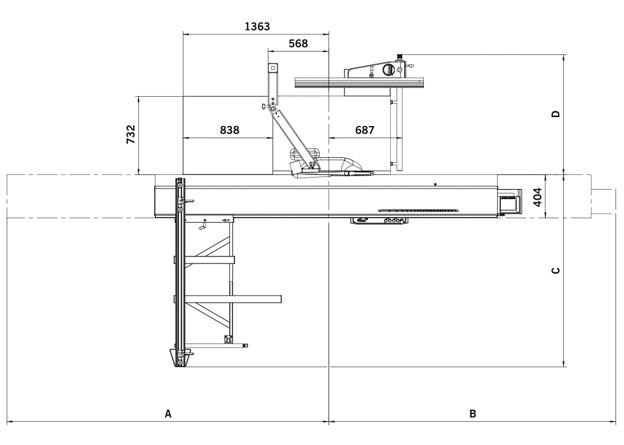

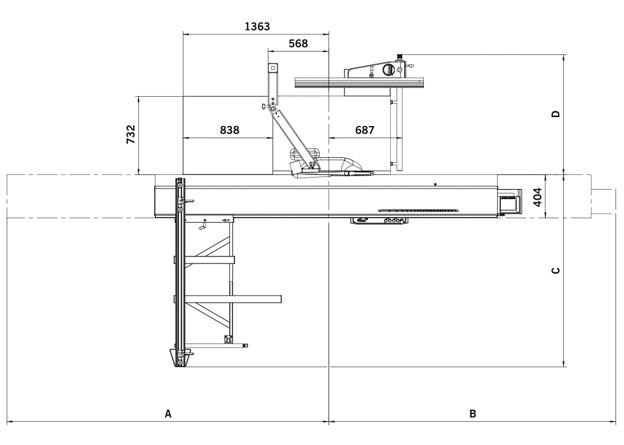

SPACE REQUIREMENTS

Your WA 8’s space requirements are as below:

| A Sliding table length + 290 mm |

| B Sliding table length + 360 mm |

| C Crosscut fence, stops to 2 500 mm: 1 445 – max. 2 630 mm Crosscut fence, stops to 3 200 mm: 1 800 – max. 3 350 mm |

| D Cutting width + 310 mm |

| Maschinengewicht 1100 kg |

| Arbeitstischhöhe 910 mm |

WA 8 T

Flexible: The Altendorf WA 8 T with manual rise/fall and tilt adjustment of the main saw blade.

The Altendorf WA 8 T adds a touch of class to any workshop. With its easy to operate manual tilt and height adjustment of the saw blade, even complex jobs can be cut quickly and efficiently with the help of the Altendorf WA 8 T.

The Altendorf WA 8 is not available in all markets.

The standard equipment of the machine may vary from country to country.

Manual rise/fall adjustment.

Manual rise/fall adjustment of the main saw blade, non-tilting saw unit

Sliding table.

The Altendorf sliding table is renowned for its smooth and exact running. This is hallmark of an Altendorf, and it all comes down to design: the table runs on large dumb bell rollers sandwiched between hard chromed guide bars, guaranteeing absolute precision. The system’s large rollers ensure smooth action, meaning the table takes less effort to move and glides as securely as if it were on rails. This quality running will endure decades of heavy load bearing in the constant presence of dust and chips, and it needs virtually no maintenance. Each time the table moves, the brush fitted to the upper part automatically cleans the round guide bars. The system operates without any lubrication. The table’s hollow multi-chamber aluminium extrusion guarantees optimal torsion resistance and rigidity. The principle of the sliding table. Wilhelm Altendorf discovered that the only way to achieve an absolutely straight edge, which in turn is required as a reference edge for precise rip and crosscutting, was to guide a static work piece through the rotating saw blade by holding it firmly on a moving support. To begin with, Wilhelm Altendorf used a wooden push slide system to guide the workpiece. In the 1930s, Altendorf developed the double roller carriage. Since the development of the aluminium sliding table in the 1950s we know of no better system than the double roller carriage in terms of smooth running, precision, torsion-resistance and low maintenance. Over 130 000 users worldwide agree with us.

Rip fence.

The rip fence is smooth and precise to adjust. The hard chromeplated round bar ensures the fence moves smoothly. If you need to divide large panels, you can swing the rip fence away under the level of the machine table.

Crosscut fence.

The robustly mounted crosscut fence enables precise cutting of 90° angles. All settings are easy to read off the slanted scales. The flip stops are robust, free of play and are easy to slide individually along the full crosscutting range.

Motor rating.

Motor rating 5.5 kW (7.5 HP), with three speeds 3/4/5 000 rpm, manually adjusted

Cutting height.

Cutting height max. 82 mm

Machine frame control panel.

The controls mounted on the panel on the machine frame are clearly identified and easy to operate. The rise and fall of the main blade is via handwheel.

Extraction hood.

The riving knife mounted protection and extraction hood allows a maximum saw blade diameter of 315 mm with a maximum cutting height of 82 mm.

Machine frame.

The WA 8 has a torsion-resistant machine frame built in the same way as the machine frames for the F 45 series. The frame design ensures very smooth running and stability. The machine frame is fully enclosed.

Saw unit.

The Altendorf saw unit is the engineering heart of all our saws. It is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly: this is because it is electronically balanced as a fully assembled unit, and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

Scoring unit with motorised adjustment.

The scorer prevents chipping out on the underside of laminated panels. The rise and fall is motorised, the lateral adjustment manual. When the scoring blade is switched on, the scorer moves to the height stored. When either the main or scoring blade is switched off, the scorer moves back under the table. The scorer has an independent 0.75 kW (1 HP) motor and turns at 8 200 rpm.

RAPIDO.

The RAPIDO scoring system makes it easier and quicker to adjust the cutting width to match that of the main blade. How quick? About three minutes, max! Compared to working with shims, where you have to take the blade off the machine to alter its width, the RAPIDO saves at least ten minutes, as the blade stays on the machine during adjustment. Adjustment is continuous so the RAPIDO can be fine-tuned to match any main blade.

Adjustment range: 2.8 – 3.8 mm.

Rip fence with fine adjustment.

Manual fine adjustment enables the rip fence to be adjusted precisely. The fence can be set with pinpoint precision by means of the adjusting screw.

DIGIT X.

A digital cutting width display for the rip fence with manual fine adjustment. This electronic measuring system guarantees rapid, precise adjustment of the rip fence. DIGIT X also offers repeat accuracy: the fence can be moved and then returned to exactly where it was previously. The system is immune to both wear and dust. Dimensions are corrected automatically when the fence is changed from the upright to the flat position.

Large extraction hood.

The large Altendorf extraction and safety hood system boasts a design which ensures optimised airflow. You can switch between narrow and wide hoods in seconds. The hood allows cutting heights of up to 125 mm (with or without scoring unit) and can be swung away fully to one side. This hood is available as an option for the WA 8 NT and WA 8 T.

DIGIT L.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings at the same time, and allows calibration of all stops in one operation.

DUPLEX.

The DUPLEX fence makes it possible to cut any angle between 0 and 90° very quickly and exactly. At 45°, the mitre can be cut on both sides of the workpiece without having to adjust the fence. The dimensions are set using a magnifying glass, measuring scale and length compensation scale. The fence can be positioned anywhere along the length of the sliding table.

One-sided mitre fence.

The one-sided mitre fence enables precise cutting of mitres. It is easy to set and can be positioned on the sliding table with the minimum of effort.

PALIN.

Long narrow workpieces can be cut parallel or into a conical shape with absolute accuracy using the PALIN fence. As the fence itself is flush with the sliding table in the vertical plane and the workpiece is laid sideways against the stop, there is no reduction in cutting length and workpieces of differing lengths can be cut without moving the fence up and down the sliding table. With the measuring system removed, the fence acts as an additional workpiece support. Also available in digital form as PALIN D.

STEG.

Enlarges support area (width: 400 mm) for wider workpieces. Makes it much easier to size large panels.

DUST EXTRACTION CONNECTION

| Top connection: | small extraction hood: Ø = 50 mm, large extraction hood: Ø = 80 mm |

| Bottom connection: | Ø = 120 mm |

| Pressure drop: | 1 500 Pa with a total connection diameter, Ø = 140 mm |

| Minimum air requirement: | Vmin = 1 150 m3/h at 20 m/sec. |

ELECTRICAL POWER REQUIREMENTS

| Motor (kW) | 5,5 |

| Voltage (V) | 380 – 420 |

| Frequency (Hz) | 50 |

| Current (A) without/with scorer | 11,5/13,5 |

| Fuses/circuit breakers (A) | 25 |

3) The cross section of the mains cable depends on the machine’s distance from the power source and must be determined by a qualified electrician (Power drop in the input cable ≤ 3 %). Please contact your Altendorf sales partner if your power supply does not match the requirements shown.

CUTTING WIDTHS

| Cutting widths (mm) | 1 000 | 1 300 |

SLIDING TABLE CUTTING LENGTH

| Maximum cutting lengths when using clamping shoe or crosscut fence | ||||

| Table length (mm) | 2 000 | 2 600 | 3 000 | 3 200 |

| Cutting length (mm) | 1 905 | 2 505 | 2 905 | 3 105 |

CUTTING HEIGHTS

| With or without scoring saw blade | |||||

| Saw blade diameter (mm) | 250 | 300 | 315 | 350 | 400 |

| Cutting heights, vertical (mm) | 0-50 | 0-75 | 0-82 | 0-100 | 0-125 |

| Cutting heights at 45° (mm) | 0-33 | 0-50 | 0-56 | 0-70 | 0-87 |

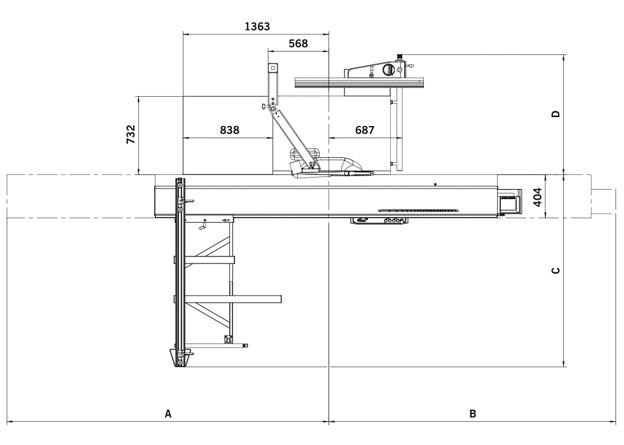

SPACE REQUIREMENTS

Your WA 8’s space requirements are as below:

| A Sliding table length + 290 mm |

| B Sliding table length + 360 mm |

| C Crosscut fence, stops to 2 500 mm: 1 445 – max. 2 630 mm Crosscut fence, stops to 3 200 mm: 1 800 – max. 3 350 mm |

| D Cutting width + 310 mm |

| Maschinengewicht 1100 kg |

| Arbeitstischhöhe 910 mm |

WA 8 TE

Accurate: The Altendorf WA 8 TE with motorised rise/fall and tilt adjustment of the main saw blade.

Ergonomic controls: With the Altendorf WA 8 TE the height and angle of the blade are simply adjusted at the press of a button. The digital display of the angle remains in your field of vision at all times during the cutting operation.

The Altendorf WA 8 is not available in all markets.

The standard equipment of the machine may vary from country to country.

Manual rise/fall adjustment.

Manual rise/fall adjustment of the main saw blade, non-tilting saw unit

Sliding table.

The Altendorf sliding table is renowned for its smooth and exact running. This is hallmark of an Altendorf, and it all comes down to design: the table runs on large dumb bell rollers sandwiched between hard chromed guide bars, guaranteeing absolute precision. The system’s large rollers ensure smooth action, meaning the table takes less effort to move and glides as securely as if it were on rails. This quality running will endure decades of heavy load bearing in the constant presence of dust and chips, and it needs virtually no maintenance. Each time the table moves, the brush fitted to the upper part automatically cleans the round guide bars. The system operates without any lubrication. The table’s hollow multi-chamber aluminium extrusion guarantees optimal torsion resistance and rigidity. The principle of the sliding table. Wilhelm Altendorf discovered that the only way to achieve an absolutely straight edge, which in turn is required as a reference edge for precise rip and crosscutting, was to guide a static work piece through the rotating saw blade by holding it firmly on a moving support. To begin with, Wilhelm Altendorf used a wooden push slide system to guide the workpiece. In the 1930s, Altendorf developed the double roller carriage. Since the development of the aluminium sliding table in the 1950s we know of no better system than the double roller carriage in terms of smooth running, precision, torsion-resistance and low maintenance. Over 130 000 users worldwide agree with us.

Rip fence.

The rip fence is smooth and precise to adjust. The hard chromeplated round bar ensures the fence moves smoothly. If you need to divide large panels, you can swing the rip fence away under the level of the machine table.

Crosscut fence.

The robustly mounted crosscut fence enables precise cutting of 90° angles. All settings are easy to read off the slanted scales. The flip stops are robust, free of play and are easy to slide individually along the full crosscutting range.

Motor rating.

Motor rating 5.5 kW (7.5 HP), with three speeds 3/4/5 000 rpm, manually adjusted

Cutting height.

Cutting height max. 82 mm

Machine frame control panel.

The controls mounted on the panel on the machine frame are clearly identified and easy to operate. The rise and fall of the main blade is via handwheel.

Extraction hood.

The riving knife mounted protection and extraction hood allows a maximum saw blade diameter of 315 mm with a maximum cutting height of 82 mm.

Machine frame.

The WA 8 has a torsion-resistant machine frame built in the same way as the machine frames for the F 45 series. The frame design ensures very smooth running and stability. The machine frame is fully enclosed.

Saw unit.

The Altendorf saw unit is the engineering heart of all our saws. It is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly: this is because it is electronically balanced as a fully assembled unit, and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

Scoring unit with motorised adjustment.

The scorer prevents chipping out on the underside of laminated panels. The rise and fall is motorised, the lateral adjustment manual. When the scoring blade is switched on, the scorer moves to the height stored. When either the main or scoring blade is switched off, the scorer moves back under the table. The scorer has an independent 0.75 kW (1 HP) motor and turns at 8 200 rpm.

RAPIDO.

The RAPIDO scoring system makes it easier and quicker to adjust the cutting width to match that of the main blade. How quick? About three minutes, max! Compared to working with shims, where you have to take the blade off the machine to alter its width, the RAPIDO saves at least ten minutes, as the blade stays on the machine during adjustment. Adjustment is continuous so the RAPIDO can be fine-tuned to match any main blade.

Adjustment range: 2.8 – 3.8 mm.

Rip fence with fine adjustment.

Manual fine adjustment enables the rip fence to be adjusted precisely. The fence can be set with pinpoint precision by means of the adjusting screw.

DIGIT X.

A digital cutting width display for the rip fence with manual fine adjustment. This electronic measuring system guarantees rapid, precise adjustment of the rip fence. DIGIT X also offers repeat accuracy: the fence can be moved and then returned to exactly where it was previously. The system is immune to both wear and dust. Dimensions are corrected automatically when the fence is changed from the upright to the flat position.

Large extraction hood.

The large Altendorf extraction and safety hood system boasts a design which ensures optimised airflow. You can switch between narrow and wide hoods in seconds. The hood allows cutting heights of up to 125 mm (with or without scoring unit) and can be swung away fully to one side. This hood is available as an option for the WA 8 NT and WA 8 T.

DIGIT L.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings at the same time, and allows calibration of all stops in one operation.

DUPLEX.

The DUPLEX fence makes it possible to cut any angle between 0 and 90° very quickly and exactly. At 45°, the mitre can be cut on both sides of the workpiece without having to adjust the fence. The dimensions are set using a magnifying glass, measuring scale and length compensation scale. The fence can be positioned anywhere along the length of the sliding table.

One-sided mitre fence.

The one-sided mitre fence enables precise cutting of mitres. It is easy to set and can be positioned on the sliding table with the minimum of effort.

PALIN.

Long narrow workpieces can be cut parallel or into a conical shape with absolute accuracy using the PALIN fence. As the fence itself is flush with the sliding table in the vertical plane and the workpiece is laid sideways against the stop, there is no reduction in cutting length and workpieces of differing lengths can be cut without moving the fence up and down the sliding table. With the measuring system removed, the fence acts as an additional workpiece support. Also available in digital form as PALIN D.

STEG.

Enlarges support area (width: 400 mm) for wider workpieces. Makes it much easier to size large panels.

DUST EXTRACTION CONNECTION

| Top connection: | small extraction hood: Ø = 50 mm, large extraction hood: Ø = 80 mm |

| Bottom connection: | Ø = 120 mm |

| Pressure drop: | 1 500 Pa with a total connection diameter, Ø = 140 mm |

| Minimum air requirement: | Vmin = 1 150 m3/h at 20 m/sec. |

ELECTRICAL POWER REQUIREMENTS

| Motor (kW) | 5,5 |

| Voltage (V) | 380 – 420 |

| Frequency (Hz) | 50 |

| Current (A) without/with scorer | 11,5/13,5 |

| Fuses/circuit breakers (A) | 25 |

3) The cross section of the mains cable depends on the machine’s distance from the power source and must be determined by a qualified electrician (Power drop in the input cable ≤ 3 %). Please contact your Altendorf sales partner if your power supply does not match the requirements shown.

CUTTING WIDTHS

| Cutting widths (mm) | 1 000 | 1 300 |

SLIDING TABLE CUTTING LENGTH

| Maximum cutting lengths when using clamping shoe or crosscut fence | ||||

| Table length (mm) | 2 000 | 2 600 | 3 000 | 3 200 |

| Cutting length (mm) | 1 905 | 2 505 | 2 905 | 3 105 |

CUTTING HEIGHTS

| With or without scoring saw blade | |||||

| Saw blade diameter (mm) | 250 | 300 | 315 | 350 | 400 |

| Cutting heights, vertical (mm) | 0-50 | 0-75 | 0-82 | 0-100 | 0-125 |

| Cutting heights at 45° (mm) | 0-33 | 0-50 | 0-56 | 0-70 | 0-87 |

SPACE REQUIREMENTS

Your WA 8’s space requirements are as below:

| A Sliding table length + 290 mm |

| B Sliding table length + 360 mm |

| C Crosscut fence, stops to 2 500 mm: 1 445 – max. 2 630 mm Crosscut fence, stops to 3 200 mm: 1 800 – max. 3 350 mm |

| D Cutting width + 310 mm |

| Maschinengewicht 1100 kg |

| Arbeitstischhöhe 910 mm |

WA 8 X

Ergonomic: The Altendorf WA 8 X with three motorised axes.

Number one for ease of operation and ergonomics: The eye level control panel of the Altendorf WA 8 X can be pivoted to the most convenient position for the operator. The rip fence is motorised.

The Altendorf WA 8 is not available in all markets.

The standard equipment of the machine may vary from country to country.

Manual rise/fall adjustment.

Manual rise/fall adjustment of the main saw blade, non-tilting saw unit

Eye-level operating panel.

All major control functions are always visible. The panel pivots into the most convenient position and is accessible from both sides of the machine. Adjustment of both the saw blade and the rip fence are motorised.

Sliding table.

The Altendorf sliding table is renowned for its smooth and exact running. This is hallmark of an Altendorf, and it all comes down to design: the table runs on large dumb bell rollers sandwiched between hard chromed guide bars, guaranteeing absolute precision. The system’s large rollers ensure smooth action, meaning the table takes less effort to move and glides as securely as if it were on rails. This quality running will endure decades of heavy load bearing in the constant presence of dust and chips, and it needs virtually no maintenance. Each time the table moves, the brush fitted to the upper part automatically cleans the round guide bars. The system operates without any lubrication. The table’s hollow multi-chamber aluminium extrusion guarantees optimal torsion resistance and rigidity. The principle of the sliding table. Wilhelm Altendorf discovered that the only way to achieve an absolutely straight edge, which in turn is required as a reference edge for precise rip and crosscutting, was to guide a static work piece through the rotating saw blade by holding it firmly on a moving support. To begin with, Wilhelm Altendorf used a wooden push slide system to guide the workpiece. In the 1930s, Altendorf developed the double roller carriage. Since the development of the aluminium sliding table in the 1950s we know of no better system than the double roller carriage in terms of smooth running, precision, torsion-resistance and low maintenance. Over 130 000 users worldwide agree with us.

Rip fence.

The rip fence is smooth and precise to adjust. The hard chromeplated round bar ensures the fence moves smoothly. If you need to divide large panels, you can swing the rip fence away under the level of the machine table.

Crosscut fence.

The robustly mounted crosscut fence enables precise cutting of 90° angles. All settings are easy to read off the slanted scales. The flip stops are robust, free of play and are easy to slide individually along the full crosscutting range.

Motor rating.

Motor rating 5.5 kW (7.5 HP), with three speeds 3/4/5 000 rpm, manually adjusted

Cutting height.

Cutting height max. 82 mm

Machine frame control panel.

The controls mounted on the panel on the machine frame are clearly identified and easy to operate. The rise and fall of the main blade is via handwheel.

Extraction hood.

The riving knife mounted protection and extraction hood allows a maximum saw blade diameter of 315 mm with a maximum cutting height of 82 mm.

Machine frame.

The WA 8 has a torsion-resistant machine frame built in the same way as the machine frames for the F 45 series. The frame design ensures very smooth running and stability. The machine frame is fully enclosed.

Saw unit.

The Altendorf saw unit is the engineering heart of all our saws. It is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly: this is because it is electronically balanced as a fully assembled unit, and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

Scoring unit with motorised adjustment.

The scorer prevents chipping out on the underside of laminated panels. The rise and fall is motorised, the lateral adjustment manual. When the scoring blade is switched on, the scorer moves to the height stored. When either the main or scoring blade is switched off, the scorer moves back under the table. The scorer has an independent 0.75 kW (1 HP) motor and turns at 8 200 rpm.

RAPIDO.

The RAPIDO scoring system makes it easier and quicker to adjust the cutting width to match that of the main blade. How quick? About three minutes, max! Compared to working with shims, where you have to take the blade off the machine to alter its width, the RAPIDO saves at least ten minutes, as the blade stays on the machine during adjustment. Adjustment is continuous so the RAPIDO can be fine-tuned to match any main blade.

Adjustment range: 2.8 – 3.8 mm.

Rip fence with fine adjustment.

Manual fine adjustment enables the rip fence to be adjusted precisely. The fence can be set with pinpoint precision by means of the adjusting screw.

DIGIT X.

A digital cutting width display for the rip fence with manual fine adjustment. This electronic measuring system guarantees rapid, precise adjustment of the rip fence. DIGIT X also offers repeat accuracy: the fence can be moved and then returned to exactly where it was previously. The system is immune to both wear and dust. Dimensions are corrected automatically when the fence is changed from the upright to the flat position.

Large extraction hood.

The large Altendorf extraction and safety hood system boasts a design which ensures optimised airflow. You can switch between narrow and wide hoods in seconds. The hood allows cutting heights of up to 125 mm (with or without scoring unit) and can be swung away fully to one side. This hood is available as an option for the WA 8 NT and WA 8 T.

DIGIT L.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings at the same time, and allows calibration of all stops in one operation.

DUPLEX.

The DUPLEX fence makes it possible to cut any angle between 0 and 90° very quickly and exactly. At 45°, the mitre can be cut on both sides of the workpiece without having to adjust the fence. The dimensions are set using a magnifying glass, measuring scale and length compensation scale. The fence can be positioned anywhere along the length of the sliding table.

One-sided mitre fence.

The one-sided mitre fence enables precise cutting of mitres. It is easy to set and can be positioned on the sliding table with the minimum of effort.

PALIN.

Long narrow workpieces can be cut parallel or into a conical shape with absolute accuracy using the PALIN fence. As the fence itself is flush with the sliding table in the vertical plane and the workpiece is laid sideways against the stop, there is no reduction in cutting length and workpieces of differing lengths can be cut without moving the fence up and down the sliding table. With the measuring system removed, the fence acts as an additional workpiece support. Also available in digital form as PALIN D.

STEG.

Enlarges support area (width: 400 mm) for wider workpieces. Makes it much easier to size large panels.

DUST EXTRACTION CONNECTION

| Top connection: | small extraction hood: Ø = 50 mm, large extraction hood: Ø = 80 mm |

| Bottom connection: | Ø = 120 mm |

| Pressure drop: | 1 500 Pa with a total connection diameter, Ø = 140 mm |

| Minimum air requirement: | Vmin = 1 150 m3/h at 20 m/sec. |

ELECTRICAL POWER REQUIREMENTS

| Motor (kW) | 5,5 |

| Voltage (V) | 380 – 420 |

| Frequency (Hz) | 50 |

| Current (A) without/with scorer | 11,5/13,5 |

| Fuses/circuit breakers (A) | 25 |

3) The cross section of the mains cable depends on the machine’s distance from the power source and must be determined by a qualified electrician (Power drop in the input cable ≤ 3 %). Please contact your Altendorf sales partner if your power supply does not match the requirements shown.

CUTTING WIDTHS

| Cutting widths (mm) | 1 000 | 1 300 |

SLIDING TABLE CUTTING LENGTH

| Maximum cutting lengths when using clamping shoe or crosscut fence | ||||

| Table length (mm) | 2 000 | 2 600 | 3 000 | 3 200 |

| Cutting length (mm) | 1 905 | 2 505 | 2 905 | 3 105 |

CUTTING HEIGHTS

| With or without scoring saw blade | |||||

| Saw blade diameter (mm) | 250 | 300 | 315 | 350 | 400 |

| Cutting heights, vertical (mm) | 0-50 | 0-75 | 0-82 | 0-100 | 0-125 |

| Cutting heights at 45° (mm) | 0-33 | 0-50 | 0-56 | 0-70 | 0-87 |

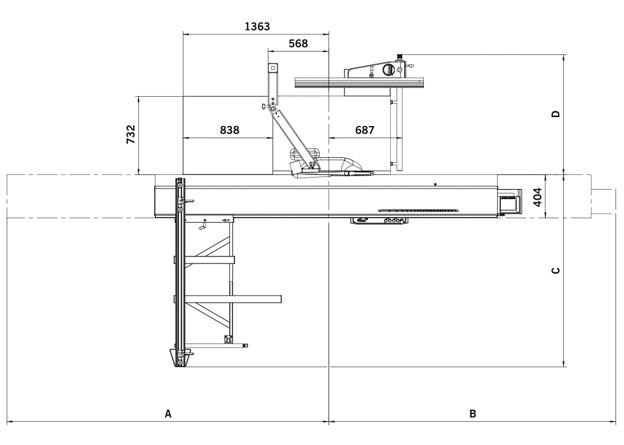

SPACE REQUIREMENTS

Your WA 8’s space requirements are as below:

| A Sliding table length + 290 mm |

| B Sliding table length + 360 mm |

| C Crosscut fence, stops to 2 500 mm: 1 445 – max. 2 630 mm Crosscut fence, stops to 3 200 mm: 1 800 – max. 3 350 mm |

| D Cutting width + 310 mm |

| Maschinengewicht 1100 kg |

| Arbeitstischhöhe 910 mm |

W8 Some illustrations of machines depict special equipment which is not included in the basic price.